All our synthetic fibers are corrosion resistant, antimagnetic, alkali resistant, chemically inert, and exhibit excellent freeze-thaw resistance.

Synthetic Microfibers

Our Fibermesh 300e3, Fibermesh 150 and Fibercast 500 polypropylene microfibers are used mainly in industrial floors, top-layer and bottom-layer concretes, and in screeds and walls. They optimize the shrinkage behavior of concrete and, as a result, reduce the formation of shrinkage cracks to a minimum. They also improve concrete properties by increasing fire resistance, shock and impact resistance, and abrasion resistance. Moreover, they significantly enhance the concrete's freeze-thaw behavior and provide it with better general durability. Typically, the fiber material is admixed in quantities of 1-2 bags (0.9 kg) per cubic meter of concrete.

Fibercast 500

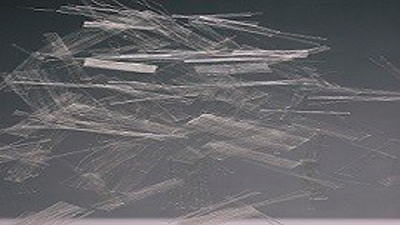

Synthetic Macrofibers

High performance fibers such as our Fibermesh 650 or Enduro HPP fibers are mostly employed in floor slabs, external basement walls, concrete roads, parking decks, underground car parks, coated industrial floors, prefab components, and shotcrete. They possess tested post-cracking tensile strength and impart to hardened concrete additional strength and resistance to dynamic loading. Our "macros" help achieve a substantial improvement of the concrete's effective performance as well as of its load deformation behavior. Depending on application and fiber type, the material is dosed in quantities of 2-9 kg of fibers per cubic meter of concrete.